Controlling Production

Tidal Automation follows certain concepts when it compiles a production schedule. The concepts are basic but can result in complicated timing scenarios with date shifts that cause confusion among users when put into practice. The most complex timing issues arise from the shifting of the start of the production day through a series of time offsets as scheduled jobs run.

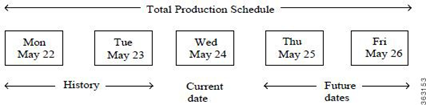

TA compiles a production schedule from your job rules for each Master. This production schedule covers at least the current day but may extend to multiple days. You determine the duration of each schedule by specifying the number of days to include. Each Master in your network has its own production schedule, so schedule durations can vary. The active production schedule for a Master includes history data (for dates past), the current date and any remaining days in the schedule (future).

The following image provides an example for a normal schedule length.

The production day contains all of the job rules that are scheduled to run during the production day. A production day always contains 24 hours and by default starts at midnight and ends at 23:59:59 PM. (For simplicity’s sake, we will use the 24-hour time format in this discussion so 11:59 PM is 2359.) To accommodate all of the processing needs of a business, a production day often differs from the calendar day. You can designate that the production day start at any time. For instance, you might specify that the production day starts at 0500 instead of starting at midnight to allow for the completion of the previous day's jobs. This is called a production day offset.

If the offset is positive, the fiscal day begins at some time after midnight and continues into the next calendar day. If the offset is negative, the fiscal day begins at some time before midnight. The maximum offset that you can define is 23 hours and 55 minutes. TA uses the designated start of the production day to determine when the production day starts, and to select and launch jobs accordingly.